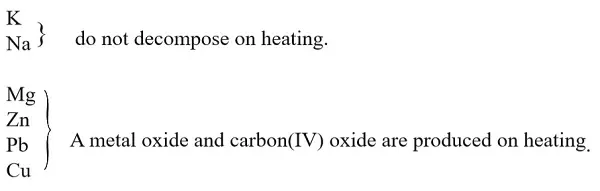

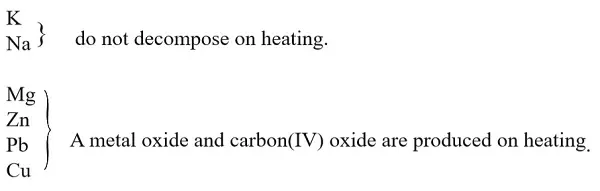

- It will be observed that some carbonates decompose when heated and others do not.

- Carbonates of:

- (NH

4)

2CO

3 produces carbon(IV) oxide, water and ammonia gas on heating.

- Therefore, the carbonates of metals high in the reactivity series do not decompose.

- Ease of decomposition of metal carbonates increases as we go down the reactivity series.

- The following are equations showing decomposition of carbonates.

Copper carbonate → copper(II) oxide + carbon(IV) oxide

CuCO

3(s)

(green) → CuO(s)

(black) + CO

2(g)

Magnesium carbonate → magnesium(II) oxide + carbon(IV) oxide

MgCO

3(s)

(white) → MgO(s)

(white) + CO

2(g)

Zinc carbonate → zinc oxide + carbon(IV) oxide

ZnCO

3(s)

(white) → ZnO(s)

(white) + CO

2(g)

Lead carbonate → lead(II) oxide + carbon(IV) oxide

PbCO

3(s)

(white) → PbO(s)

(yellow)) + CO

2(g)

Calcium carbonate → calcium oxide + carbon(IV) oxide

CaCO

3(s)

(white) → CaO(s)

(white) + CO

2(g)

- Copper(II) oxide is black, while oxides of magnesium and calcium are white.

- Zinc oxide is yellow when hot and white on cooling.

- Lead(II) oxide is red-brown when hot and yellow on cooling.

- Sodium carbonate and potassium do not decompose on heating.

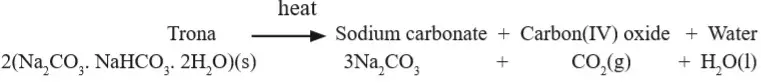

- Sodium hydrogencarbonate and calcium hydrogencarbonate decompose on heating to form a carbonate, water and carbon(IV) oxide.

Sodium hydrogencarbonate → sodium carbonate + carbon(IV) oxide + water

2NaHCO

3(s) → Na

2CO

3(s) + CO

2(g) + H

2O(l)

Calcium hydrogencarbonate → calcium carbonate + carbon(IV) oxide + water

Ca(HCO

3)

2(s) → CaCO

3(s) + CO

2(g) + H

2O(l)

- When calcium hydrogencarbonate is heated strongly calcium carbonate formed decomposes to form calcium oxide and carbon(IV) oxide.

- Ammonium carbonate decomposes on heating to form ammonia gas, water and carbon(IV) oxide.

Ammonium carbonate → ammonia + carbon(IV) oxide + water

(NH

4)

2CO

3(s) → 2NH

3 (g) + CO

2(g) + H

2O(l)

- Ammonia and carbon(IV) oxide gases are liberated at the same time.

- If moist red and blue litmus papers are put together at the mouth of the test-tube when ammonium carbonate is heated, ammonia gas is detected first

red litmus paper turns blue.

Note: Sometimes sodium carbonate may be contaminated with sodium hydrogencarbonate and therefore carbon(IV) oxide can be obtained on heating it.

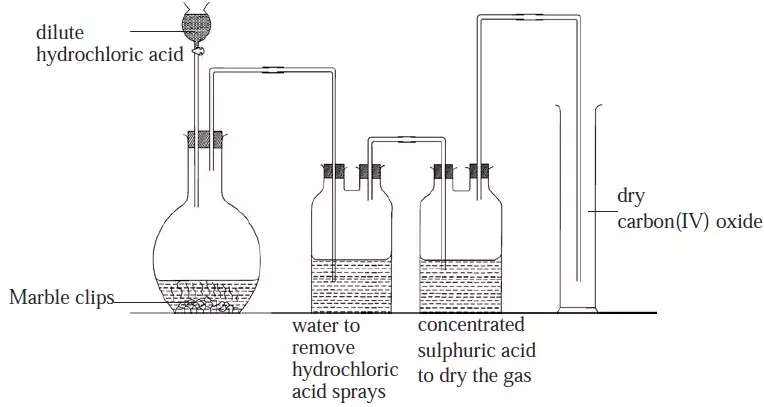

Action of Dilute Acids on Carbonates and Hydrogencarbonates

- All carbonates liberate carbon(IV) oxide on addition of a dilute acid.

- They also form a salt and water. For example:

Calcium carbonate + nitric acid → calcium Nitrate + water + carbon(IV) oxide

CaCO

3(s) + 2HNO

3(aq) → Ca(NO

3)(aq) + H

2O(l) + CO

2(g)

Calcium carbonate + hydrochloric acid → calcium chloride + water + carbon(IV) oxide

CaCO

3(s) + 2HCl(aq) → CaCl

2(aq) + H

2O(l) + CO

2(g)

All hydrogencarbonates also liberate carbon(IV) oxide on addition of an acid. For example:

Sodium hydrogen carbonate + nitric acid → sodium nitrate + carbon(IV) oxide + water

NaHCO

3(s) + HNO

3(aq) → NaNO

3(aq) + CO

2(g) + H

2O(l)

Sodium hydrogencarbonate + hydrochloric acid → sodium chloride + carbon(IV) oxide + water

NaHCO

3(s) + HCl(aq) → NaCl(aq) + CO

2(g) + H

2O(l)

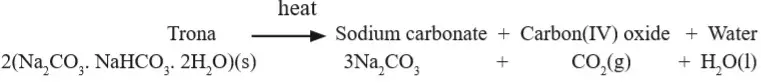

Production and Manufacture of Sodium Carbonate

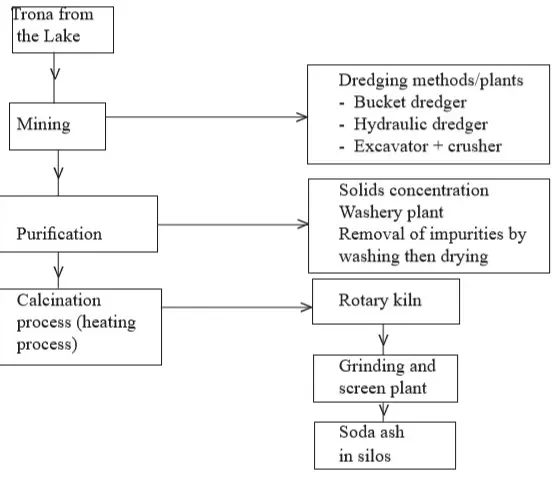

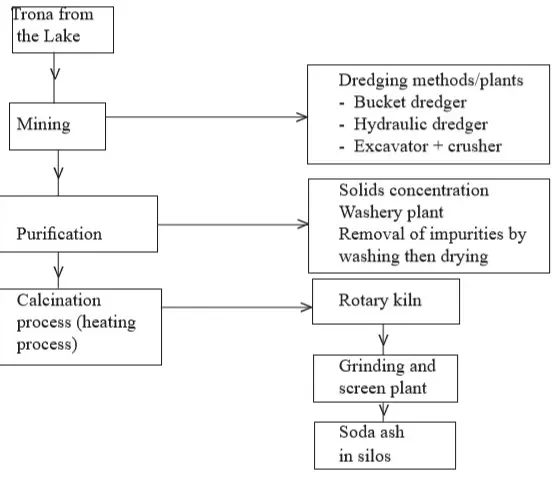

I. Production of sodium carbonate (soda ash) at Magadi Soda Company

- The most efficient means of trona extraction uses

dredging techniques.

- Both a

bucket dredge and a

cutter-suction dredge are used for this purpose, concentrating on the top 4 metres or so of the solid crust where the purest material is found.

- As the solid material is removed from the surface,

liquor (unwanted solution) from the surrounding trona drains into the resulting cavity, forming a pool or

paddock in which dredgers can float.

- The crystals of trona produced by the dredgers are mixed with liquor and pumped as slurry back to the ash plant.

- Here the liquor is discarded and the crystal washed and centrifuged.

- The dump crystals are then fed into

calciners (kilns).

- Here the residual moisture, water crystallisation and carbon(IV) oxide gas are driven off to leave normal sodium carbonate (soda ash).

- The soda ash from the calciners passes through rotary drum coolers before entering the grinding and screening plant.

- Oversize material is removed and grounded again.

- The final product is conveyed to silos where it is packed or loaded directly into specially bulk raid hopper wagons.

- The liquor from this process is used to extract sodium chloride.

- Solar evaporation process is used. Most of the Magadi sodium chloride is sold within Kenya for livestock consumption or for industrial purposes.

Figure 9: A flow chart of soda ash manufacturing process

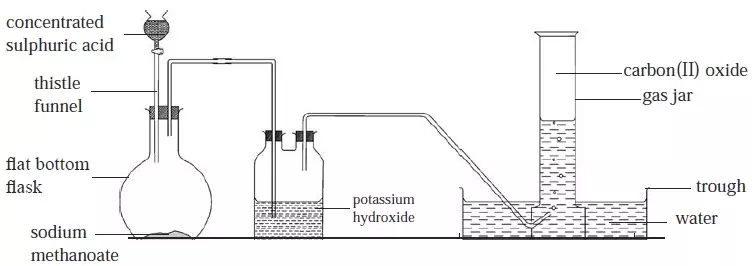

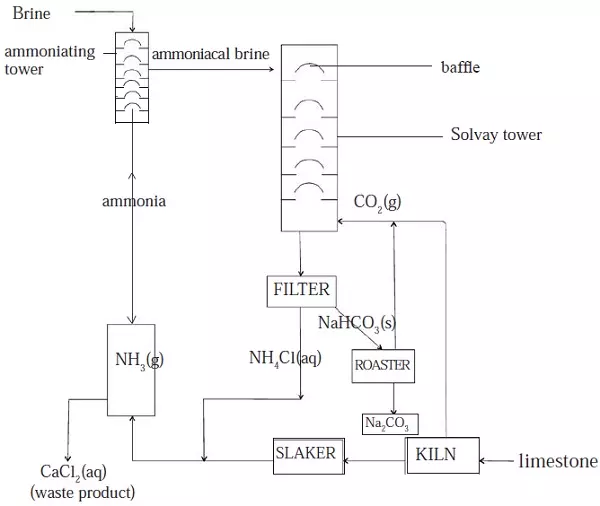

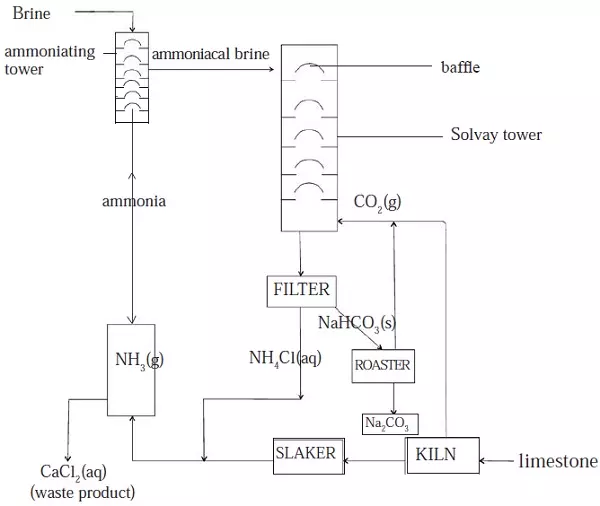

II. Manufacture of sodium carbonate (soda ash) by Solvay process

- The main raw materials are sodium chloride and calcium carbonate.

- Concentrated brine (sodium chloride solution) is saturated with ammonia in a tower.

- The ammoniacal brine formed is run down the Solvay tower.

- Carbon(IV) oxide is forced into the tower from the bottom.

- The towers are filled with baffles. These baffles make the liquid flow slowly and increase the surface area for reaction.

- Sodium hydrogen carbonate is formed in Solvay tower. The reaction occurring is as follows.

Sodium chloride + ammonia + carbon(IV) oxide + water → sodium hydrogencarbonate + ammonium chloride

NaCl(g) + NH

3(aq) + CO

2(g) + H

2O(I) → NaHCO

3(s) + NH

4Cl(aq)

- Then sodium hydrogencarbonate is filtered off, and washed to remove ammonium chloride.

- It is then heated in a furnace roaster to give sodium carbonate and carbon(IV) oxide.

Sodium hydrogencarbonate → sodium carbonate + carbon(IV) oxide + water

2NaHCO

3(s) → Na

2CO

3(s) + CO

2(g) + H

2O(l)

- Carbon(IV) oxide formed is recycled to the Solvay tower.

- The other source of carbon(IV) oxide is from heating calcium carbonate(limestone) in the kiln where it dissociates into calcium oxide and carbon(IV) oxide.

Calcium carbonate → calcium oxide + carbon(IV) oxide

CaCO

3(s) → CaO(s) + CO

2(g)

- The calcium oxide formed from above reaction is

slaked by addition of water.

Calcium oxide + water → calcium hydroxide

CaO(s) + H

2O(l) → Ca(OH)

2z(s)

Figure 10: Solvay process

- The calcium hydroxide formed is heated with the filtrate, ammonium chloride from the solvay tower, to produce ammonia.

Ammonium chloride + calcium hydroxide → calcium chloride + ammonia + water

2NH

4Cl(aq) + Ca(OH)

2(s) → CaCl

2(aq) + 2NH

3(g) + 2H

2O(l)

- The ammonia from this reaction is returned to the ammoniating tower.

- A careful examination of the flow diagram (Figure 10) shows that the only waste product in this process is calcium chloride.

- The carbon(IV) oxide and ammonia are recycled.

- Therefore, the solvay process is very efficient.

- The raw materials are cheap and readily available and only one waste product is formed.

Uses of sodium carbonate

1. Manufacture of glass.

2. In domestic water-softening.

3. In the manufacture of chemicals e.g. sodium hydroxide.

4. In the manufacture of laundry detergents.

5. In the paper-making process.

6. Textiles.